ROBRAD

FED4SAE and ROBRAD

Robustification of radar sensors for application in harsh industrial environments

Radar technology for harsh environments

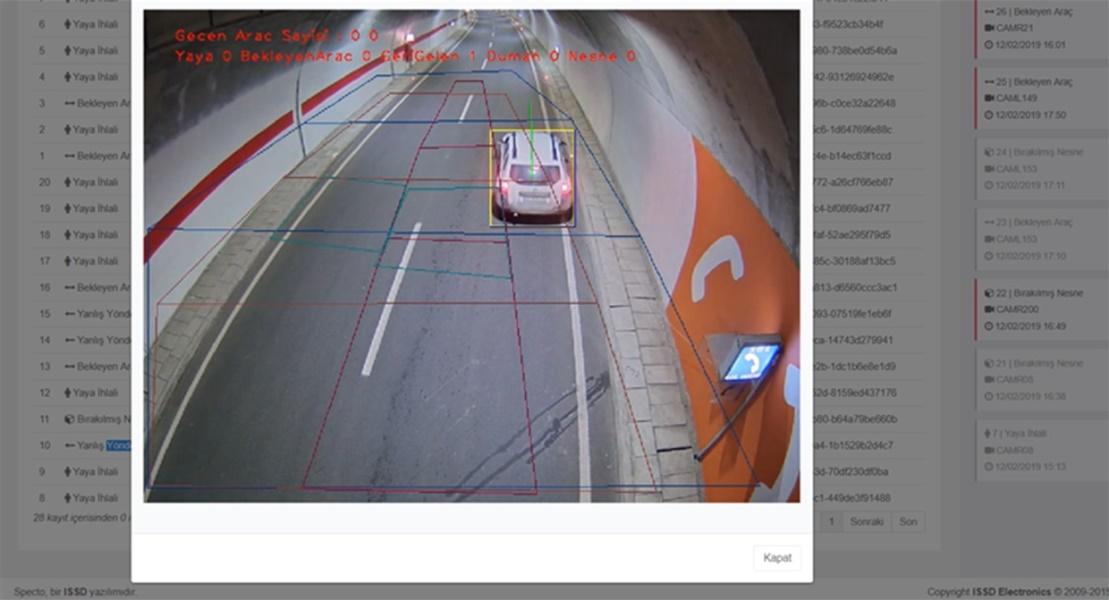

Due to the adverse environmental conditions in metal production, essential measurement technologies, e.g. optical and laser-based, reach their physical limits in various fields of application and many common sensors (optical, laser-based) are hindered from reaching their specified functionality. Thus, observation of relevant process parameters stays fragmented over the whole process-chain.

Radar-based measurements however are insensitive to the adverse conditions (e.g. high temperature, dust, air humidity, and mist from rolling emulsion or oil).

For improving the technological readiness level of such sensors, a well-structured and competently performed experiments and functionality tests are of core importance.

Robustification of Asinco’s radar-based measurement technology

In a comparison of today’s optically- or laser-based measuring systems, a previously unattained field of application, much closer to the process, has been opened.

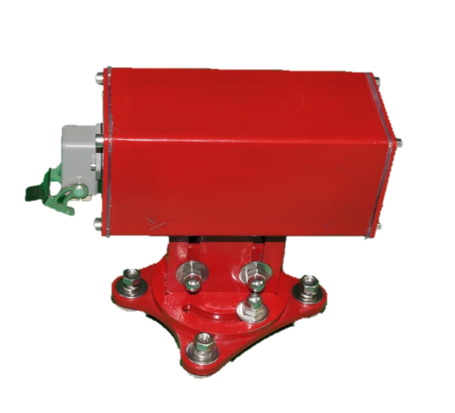

The radar-based system technology, further developed and especially robustified for the industrial application, has the potential to be used in almost every process stage of metal processing, from continuous casting (slabs) and hot rolling (hot strip, heavy plate) to cold rolling and finishing, as well as in long product plants and potentially in the production of other materials such as plastics, glass, wood and paper.

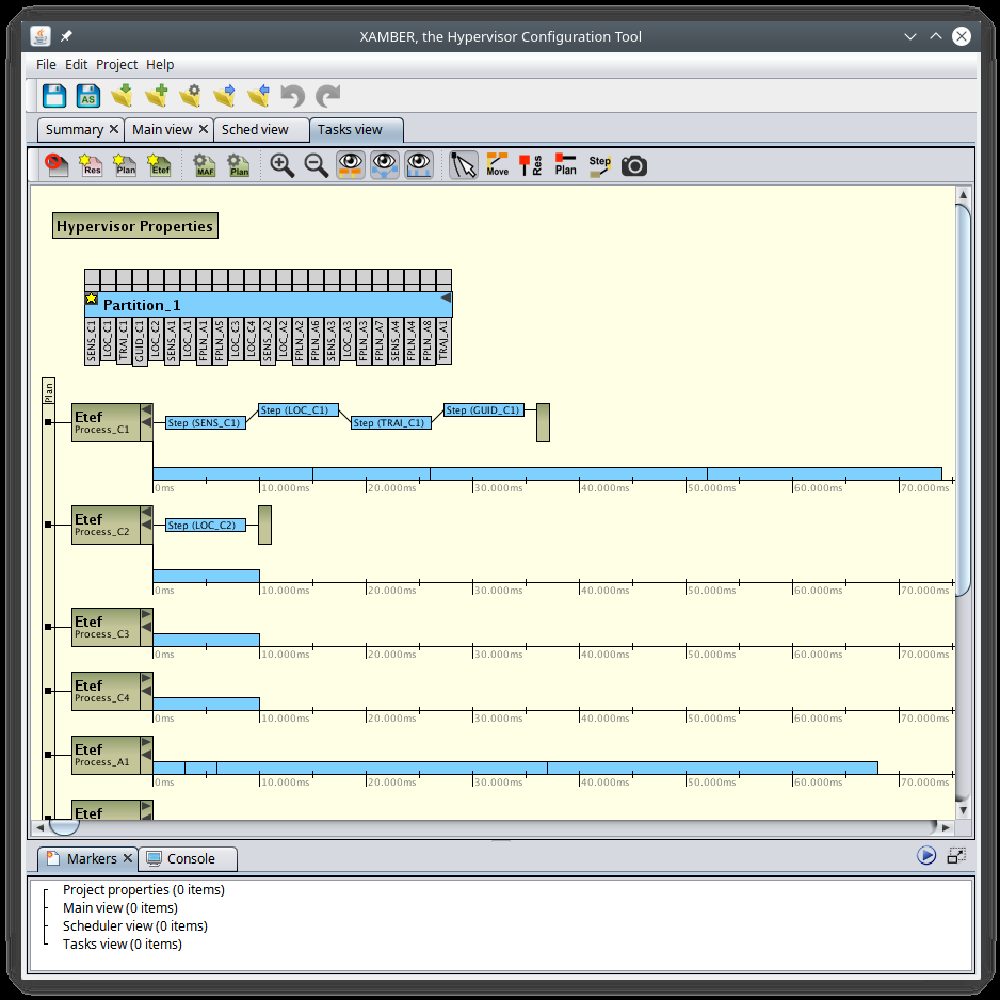

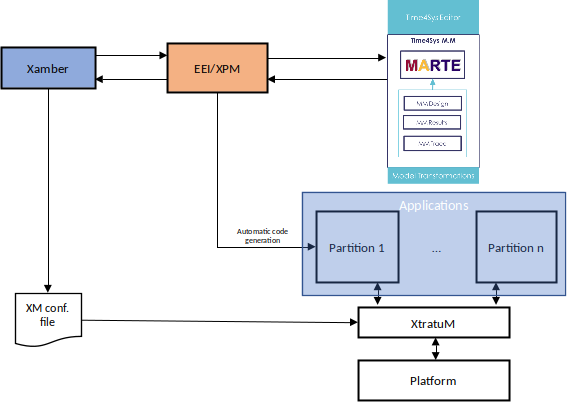

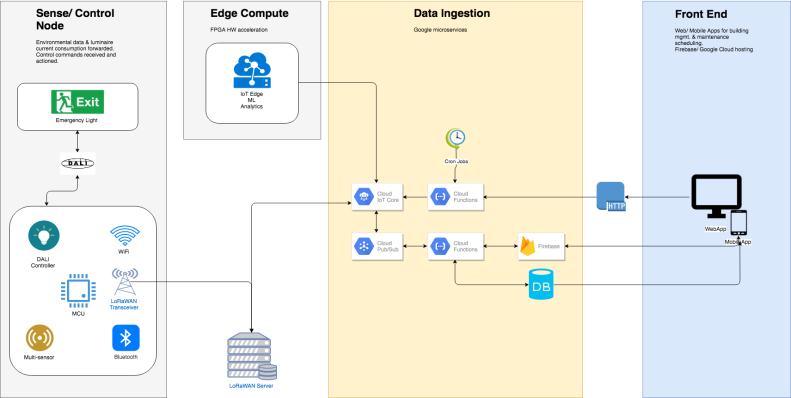

By transferring main raw data processing onto a decentralised embedded system included in the sensor, core requirements are provided for effectively implementing the sensing units as self-aware CPS in industrial environments. Due to advancement in innovative signal processing algorithms, this was achieved without any discernible disadvantages compared to existing measurement technologies.

With the introduction of this new measuring technology, possibilities for process improvement with associated energy savings are attained at many points in the metal production process.

Cost-effective, modular and reproducible solution

The project yielded an overall concept based on STM32-componetns and a test plan for a self-sufficient test-hardware.

This resulted in a first prototypical test batch of sensors which have been tested under various conditions:

- Testing and improving sensor performance in terms of real-time capabilities for digital signal processing (sampling time: up to 1 kHz)

- Testing and improving sensor protection (housing) against harsh environment conditions with long-term continuous load tests against corrosive gases

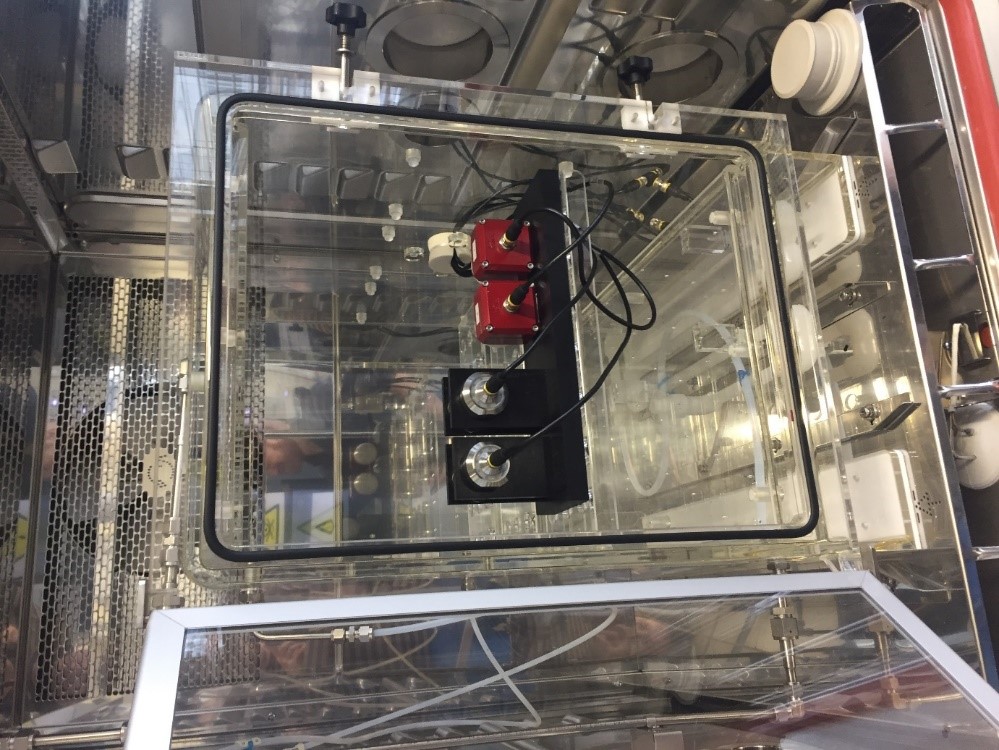

- Testing and improving sensor protection (electronic) against harsh environment conditions with long-term continuous load tests with temperatures up to 100°C and variable humidity.

Based on these tests, further adaptions of the sensors have been carried out and the final iteration showed that the design of the sensor housing can withstand the industrial conditions in the steel industry.

A test set-up will be placed in a real environment in a steel mill to carry out tests under real conditions in order to validate the sensors. Nevertheless, the prospects for a functional radar system that can prove itself under harsh industrial conditions are good.

FED4SAE support and opportunity

The increasing use of sensor intelligence and data pre-processing capabilities has been successfully facilitated in the project by using the reliable and high-performance industrialized STM hardware.

The initiation and further pursuit of the robustification and market readiness development of radar-based sensors is the main interest for ASINCO as systems currently available on the market obviously do not meet industrial requirements.

The simulation of real process environments by exploiting the functionalities of the advanced platforms of the Fraunhofer corrosive gases testbed accelerated the improvement of the technological readiness level of the radar sensors.

ASINCO is already closely interconnected within the pan-European community of radar sensors and within the steel producing community. The cross-border collaborations in FED4SAE further enhanced this and helped ASINCO to expand its leading position in the target market of providing robust measurement solutions for the metal producing industry.

|

Industry 4.0 |

ASINCO designs, develops and delivers modern and efficient solutions for plant and process automation including product-related applications. Focus is on the process industry: iron and steel industry, metallurgy, process engineering, power plants and others.

ASINCO is a pioneer of radar-based measurement technology in the process area. ASINCO has many years of experience in the development, construction and testing of differing radar measurement technology.

‘Everyone is talking about “Industry 4.0”, and if futurologists are to be believed, this technology is set to revolutionize production. To achieve this goal, new intelligent sensors and actuators as well as innovative automation solutions must be developed in addition to new safety concepts. Therefore, ASINCO offers suitable radar-based solutions from basic electronic development up to tailored measurement solutions.’

(Joaquim Denker, ASINCO)

Impact

- Radar sensor (90-120 GHz) with highest robustness, precision and real-time capability developed

- Metal industry identified as the target industry

- Forecasted growth in the target industry of about 8-10% in the next two years

- Sales of 4-5M Euro/year expected for the next two years

- Access to iron and steel industry market with a budget of 15M Euro/year in Europe and over 150M Euro/year worldwide

- Personnel growth planned for the next year to complete the product commercialisation

Supported by

![]()

Authors and Contributors: Fraunhofer, UNICAN, Digital Catapult, ASINCO

All images © ASINCO

Sentinum’s holistic sensor system allows to generate an accurate picture of the events in the canal and damage to infrastructure and people can be prevented. By recording the water level, flow rate and pressure, conclusions can be drawn in real time about events in the drainage system. The positions of manhole covers are instantly detected and warnings are transmitted to the relevant authorities, by voice call, SMS or e-mail.

Sentinum’s holistic sensor system allows to generate an accurate picture of the events in the canal and damage to infrastructure and people can be prevented. By recording the water level, flow rate and pressure, conclusions can be drawn in real time about events in the drainage system. The positions of manhole covers are instantly detected and warnings are transmitted to the relevant authorities, by voice call, SMS or e-mail. Additional, data is continuously recorded over many years and processed to provide information about changes and anomalies. This opens up a completely new perspective on the planning phase, implementation and, above all, maintenance of the sewer systems.

Additional, data is continuously recorded over many years and processed to provide information about changes and anomalies. This opens up a completely new perspective on the planning phase, implementation and, above all, maintenance of the sewer systems.

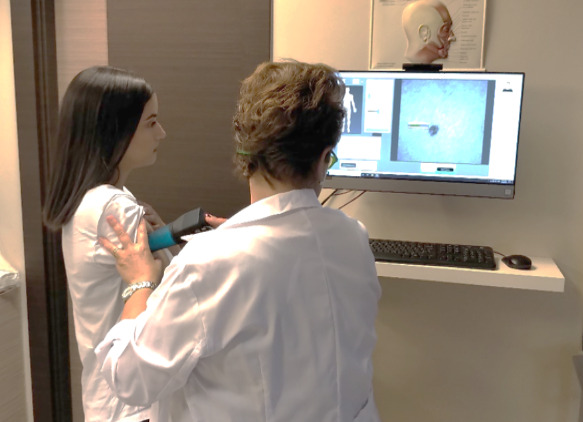

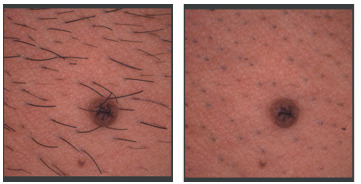

Dermoscopy refers to the examination of the skin using surface microscopy. Althexis Solutions Ltd™ has developed the Next Generation Hyperspectral Dermoscopy System which enables dermatologists to gain insights into the presence of cancerous cell tissue (melanoma) in a patient’s skin and boost their productivity through an user-friendly, touch enabled software.

Dermoscopy refers to the examination of the skin using surface microscopy. Althexis Solutions Ltd™ has developed the Next Generation Hyperspectral Dermoscopy System which enables dermatologists to gain insights into the presence of cancerous cell tissue (melanoma) in a patient’s skin and boost their productivity through an user-friendly, touch enabled software.