Time4PS

Company info:

Name: Fent Innovative Software Solutions S.L. Date founded: 2010 Number of employees: 8 Location: Despacho 03 – UPV, Pedro Duque, 7, 46022 Valencia www.fentiss.com

Partners:

Innovation Management Partner:

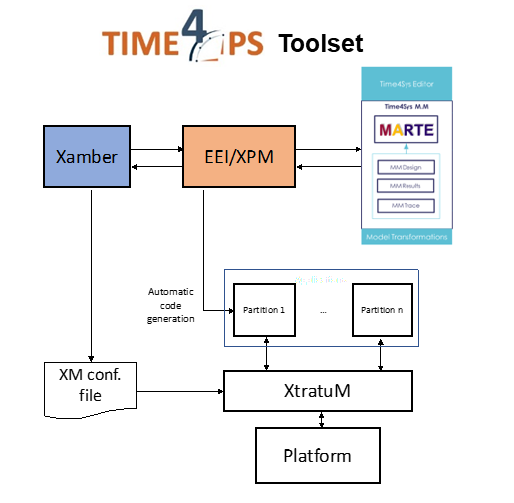

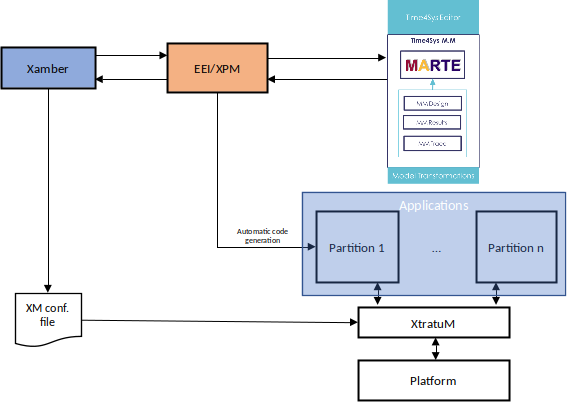

Time4PS: Fully integrated development tools for partitioned systems

Challenge

The main goal of the project is to provide a complete set of tools that covers all the phases of the life cycle of the product: from the system design to the final configuration file of the partitioned system.

Goals

- Connect our customers modelling tool with Time4Sys.

- Give Time4Sys the ability to define partitioned systems.

- Connect Time4Sys and Xamber so the timing performance verification is automatically done in Xamber.

- Demonstrate de capabilities of the partitioned framework developed by means of an application experiment in the space domain.

Solution

In the architecture proposal three tools are connected to define the complete system. A modelling design tool (EEI/XPM) that is used to model the system and generate the deployment and automatic code of the applications, Time4sys to define temporal information and a configuration tool to obtain the static configuration file for XtratuM (Xamber).

FED4SAE Support

fentISS worked at add support to Time4Sys for partitioned systems (Time4PS) and connect this new framework with Xamber, the XtratuM hypervisor scheduling analysis and configuration tool, and the corresponding modelling tool in order to close the development loop.

fentISS defined a partitioned meta-model for the generation of the final hypervisor static configuration file with which the system can be executed.

Thales provided a Flight Management System use case, its functional architecture in CAPELLA and expertise.

Impact

fentISS tool set is now able to generate a model, run the configuration and scheduling verification, and generate the deployment automatically with the Time4PS set of tools.

fentISS tool set will enable fentISS customers to use more sophisticated tools for modelling, analysis and integration of their system and it will give fentISS the ability to develop further support of their products. Also, it will empower fentISS to gain global competitiveness in three ways.

Firstly, it will allow fentISS to enter in customers who are already using Time4Sys. Secondly, it will improve the company products position in large and complex projects. Finally, the project will offer new opportunities to fentISS to enter in adjacent markets such as aviation, railways or automotive.