Aerodrums

Company info:

Name: Aerodrums

Date founded: 2011

Number of employees: 5

Location: Liverpool

We aim to democratise access to musical percussion instruments by making air drumming a reality.

aerodrums.com

Partners:

![]()

Innovation Management Partner:

Making a self-contained air drumming instrument

Challenge

We were able to bootstrap Aerodrums using readily available hardware, but this meant requiring users of our first model to own and operate a computer. The challenge is to enable people to set up and drum without a computer.

Solution

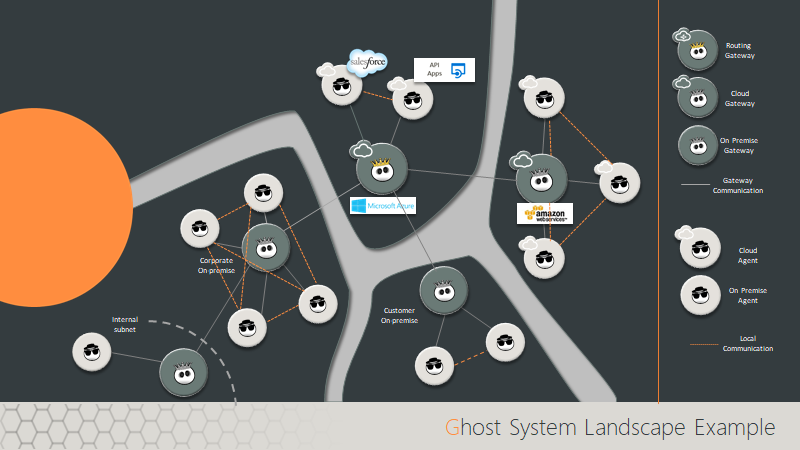

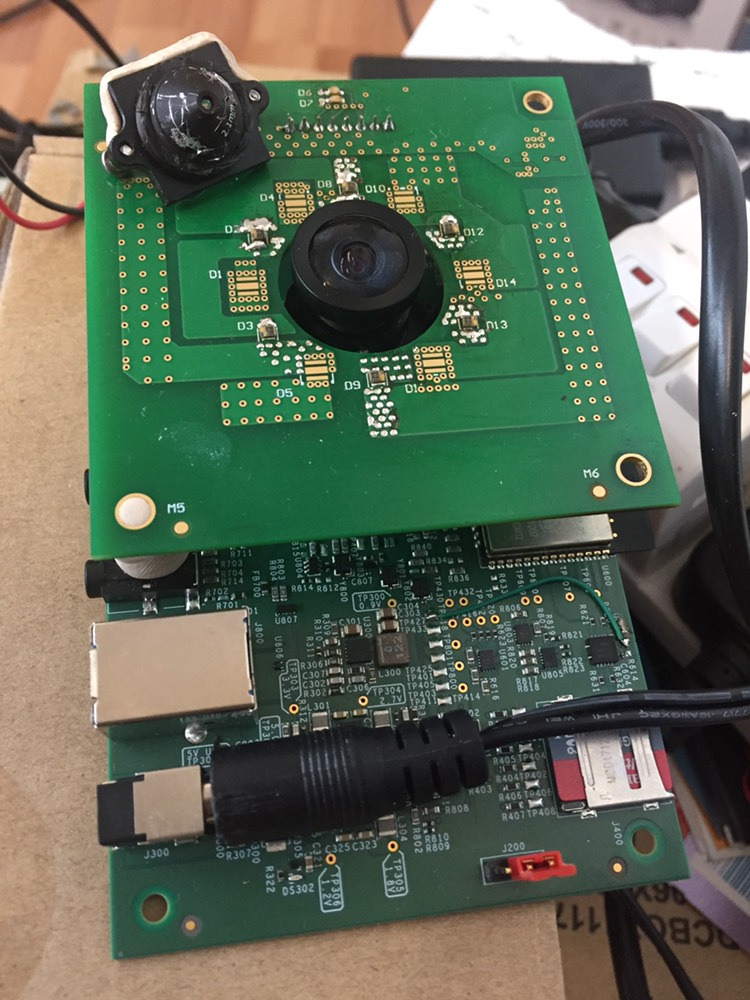

Our solution is to create an embedded IoT instrument that people can use with a mobile phone, tablet or virtual reality headset. This means solving the problem of doing high speed real time motion tracking and low latency audio rendering on an affordable IoT hardware platform. No one has tried to do this before – we are the first mover and leader in optically tracked percussion instruments.

FED4SAE Support

FED4SAE enabled us to further a collaboration with Intel; receive support from BME’s Department of Electron Devices; receive advice on the management of innovation from Blumorpho; and fund R&D. Using Intel’s Myriad 2 platform, we were able to finalise a proof of concept. We then moved on to a design-to-cost phase and completed a pre-production prototype. BME assisted us with advice on heat dissipation for LED arrays, and with characterising the behaviour of the prototype under different temperature and humidity conditions. Blumorpho helped us overcome unforeseen supply difficulties in the course of the project.

Impact

The project enabled us to de-risk the introduction of the next Aerodrums model to market, as well as reducing its cost to end users. This is key to our ambition to democratise access to percussion instruments. These fall in a category of goods that is currently difficult to use in dense housing, expensive and whose manufacturing is demanding on the environment.

When we launch the product we will be able to activate a key part of our business model, which is to offer digital goods to users of the instrument. These will include music lessons, new sounds, new instrument configurations, visual 3D “skins” and play along songs.

The above combined with the higher attractiveness to end users of a self contained instrument will allow our company to grow.