RATE

Company info:

Name: Link Software Date founded: 2002 Number of employees: 15 Location: Elgazala Technopark, Ariana, Tunisia Software engineering, consultancy and development company operating in various fields of information technology. http://www.linkconet.com

Partners:

Innovation Management Partner:

Runtime Architect – RATE

Challenge

Electronic systems with real-time performance constraints are found in many different application domains such as space, automotive, railway, aerospace, medical monitoring and imaging, industrial process control, robotics, etc.

A common trend amongst all these systems is the significant quantitative and qualitative increase of the functions to be implemented in order to respond to the growing needs for connectivity, automation, autonomy, security, etc. Among the different activities related to the development of real-time systems, Performance Engineering is one of the most challenged by this trend.

One of the major challenges today in the Performance Engineering of real-time systems is the integration of design models and runtime aspects. The timing behavior at runtime has to be matched with the design in order to identify the timing failures in design and deviations from the real-time requirements.

Solution

RATE will allow the architect performing a continuous system performance engineering cycle between design and runtime, thus ensuring the quality of the running real-time system while reducing the design and development efforts and costs, and getting valuable feedback that can be used to boost the productivity and provide lessons-learnt for future generations of the product

The following objectives will be fulfilled:

- Verify if timing requirements are met in the system execution (CPU) or communication (network/bus) and identify potential timing bottlenecks.

- Help the architect understanding the system timing behaviour based on numerical and graphical statistics for the system execution/communication.

- Perform consistency check between runtime and models to validate timing related assumptions taken at the design phase.

- Help the architect correcting timing errors and exploring design alternatives at the design phase based on the system runtime behaviour before investing time and efforts in implementing and testing.

FED4SAE Support

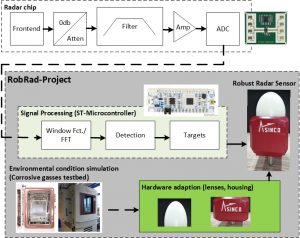

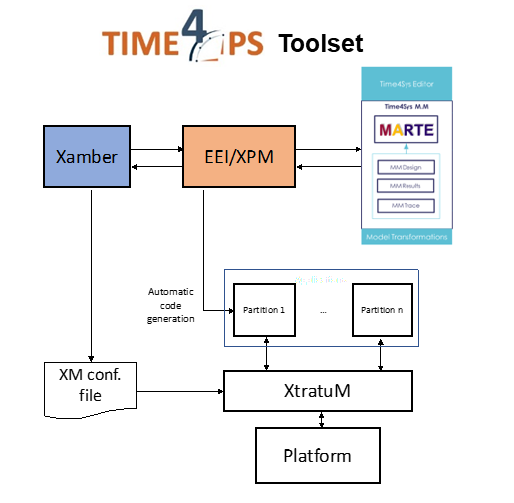

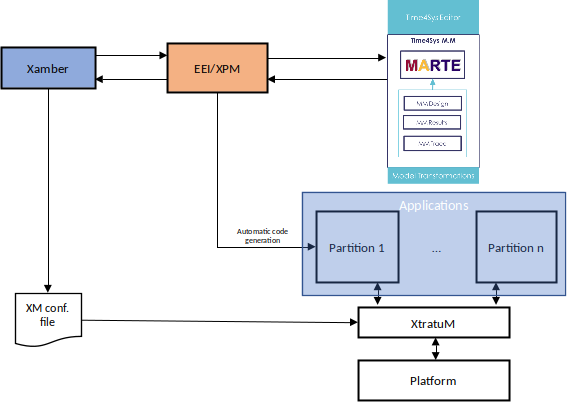

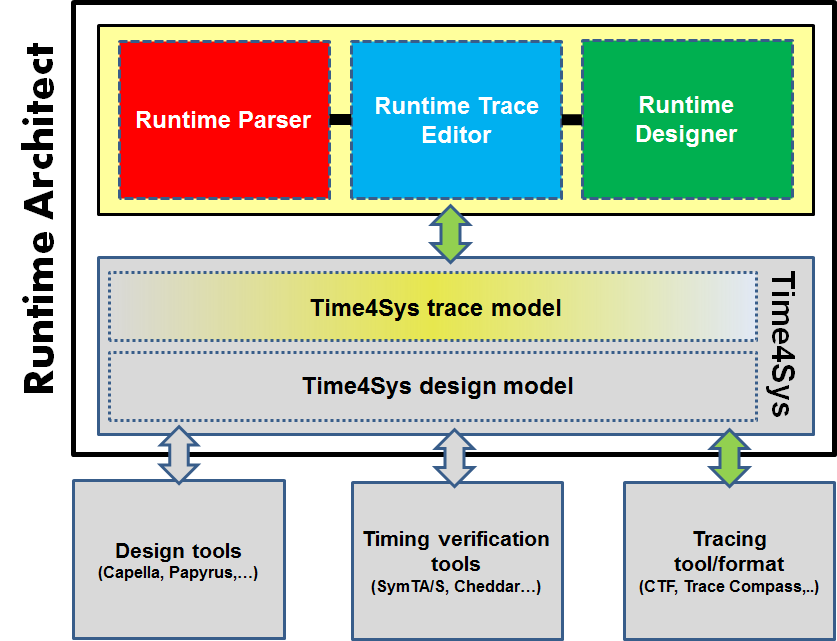

RATE has integrated theTime4Sys technology provided by THALES. By relying on the Time4Sys design model and the Time4Sys trace model, RATE then automatically benefits from current and future connections to Time4Sys of the various existing model-driven performance engineering tools such as design tools, scheduling analysis and simulation tools as well as tracing tools all at once. This guarantees high flexibility and add a valuable agnostic character to RATE by making it possible to easily integrate it in any runtime, design and any scheduling verification environment.

Impact

Runtime Architect gives to the architect access to knowledge on the system timing behavior based on the processing of runtime traces, thus allowing him to easily perform correction during validation and before delivery. Runtime Architect will allow reducing the design efforts (~15% gain estimated) while improving development efficiency as well as validation speed (~30% faster timing validation).

Through the integration of the Time4Sys technology, it becomes easy to use Runtime Architect in any runtime, design and timing verification environment, thus offering to our customer a seamlessly integrated solution that will deliver a full, round-trip support for runtime traces analysis, design modelling and timing verification.

Performance engineers have then the capability to rapidly integrate runtime aspects collected from traces into their design models. They can start from runtime traces and then change the system configuration virtually to easily predict the performance impact of modified timing properties of tasks, schedulers or hardware. Runtime Architect enables performance engineers to quickly iterate their designs as many times as they want, for both new developments and evolutionary extension and optimization of existing systems.