BETP

Company info:

Name: Kalmia d.o.o.

Date founded: 2016

Number of employees: 15

Location: Škofja Loka, Slovenia

Team of experienced software brewers gathered together with an aim to build innovative web and mobile apps for our awesome clients: choose the best technologies, build a product, design software architecture and great user experience.

Partners:

Innovation Management Partner:

BETP: Blockchain Enabled Traceability Platform

Challenge

As automotive industry is moving towards digitalization various vendors and their suppliers are looking for new ways to manipulate existing processes. New digitalization approaches will influence development and manufacturing of new vehicles in many areas including traceability.

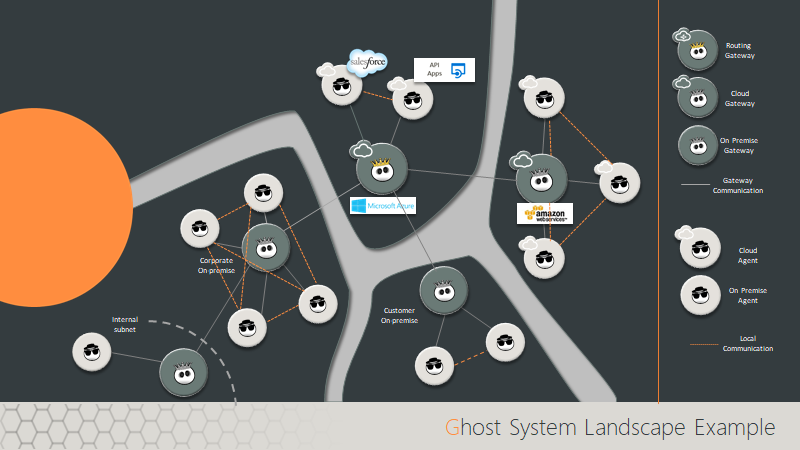

Kalmia aims to prepare a model of standalone API driven blockchain platform that is ready to integrate with future third-party business applications within various industries providing a functionality of storing, manipulating and evaluating data on the blockchain in order to provide traceability

Solution

Most of current blockchain based solutions request extensive knowledge of distributed ledger technologies by the developers and integrators to deploy applications on the top of them.

Kalmia is developing a platform that hide all the blockchain complexity and is to be blockchain agnostic. Kalmia goal is to offer solution on the top of the state-of-the-art technology and bring it closer to the industry..

FED4SAE Support

Through fruitful and constructive exchanges, AVL and fortiss brought technical support and expertise regarding:

- IODP platform features and industrial customer needs (AVL)

- The added value BETP will bring to AVL IODP platform (AVL & fortiss)

- The technical aspect of the BETP, (AVL & fortiss)

- Detailed discussion of BETP architecture (fortiss)

- Contact with potential customers in Bavaria (fortiss)

Blumorpho supported Kalmia broader business model around BETP.

FED4SAE ecosystem has helped to evaluate the true value of BETP solution, offered the opportunity of BETP product first public presentation and will continue helping with further development.

Impact

Strong impact on Kalmia future development is based by providing a stand-alone solution viable for the market. The cooperation with AVL (an industrial platform provider) has accelerated the product development and (especially) business development by providing better understanding and access to the automotive market.

This will work as a strong reference for gaining new customers inside other industries and will result in increasing our revenues and global customer base. Our blockchain and industrial digitalisation expertise is planned to provide 30% year-to-year revenue growth in next 5 years.