Information

| Partner: | Fraunhofer IISB |

| Advanced Technology: | π-Fab infrastructure |

| Contact: | Markus Pfeffer |

| Email: | Markus.Pfeffer@iisb.fraunhofer.de |

π-Fab infrastructure FRAUNHOFER (FhG)

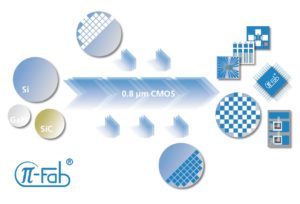

π-Fab – Low Volume Prototype Fabrication of Customized Electron Devices

Device development conducted at our institute can be transferred into a small-volume manufacturing process by ISO 9001 certified “π-Fab”. π-Fab is a joint collaboration between the Fraunhofer IISB and the Chair of Electron Devices dedicated to the realization of prototype devices under an industry-compatible fabrication environment. Fabrication ranges from single process steps across process modules up to full-fledged device fabrication including Statistical Process Control and Process Control Measurements on calibrated measurement tools. Additionally, electrical characterization for 100% device testing is available. These activities allow for the first phase of a product ramp-up when fabrication capacities by foundries – due to non-standard CMOS technology requirements – or the global players in power device fabrication are not yet available due to the low production values.

π-Fab facts:

- P rocess line based on 0.8 µm CMOS technology

- Wafers: Si, SiC, and others

- Wafer sizes: samples to 200 mm

- Devices

- CMOS

- Power

- Sensors

- MEMS

- Passives

For more information:

Markus Pfeffer

Fraunhofer IISB, Erlangen, Germany

Markus.Pfeffer@iisb.fraunhofer.de

https://www.iisb.fraunhofer.de/

https://eurocps.org/design-centers/fhg-germany/